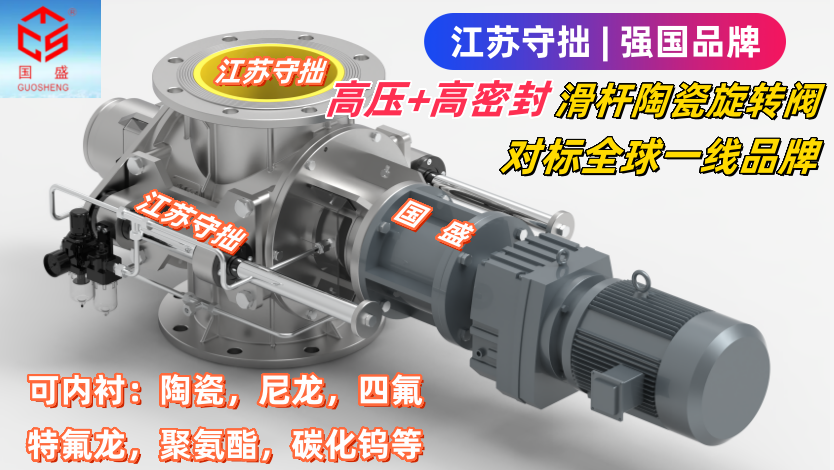

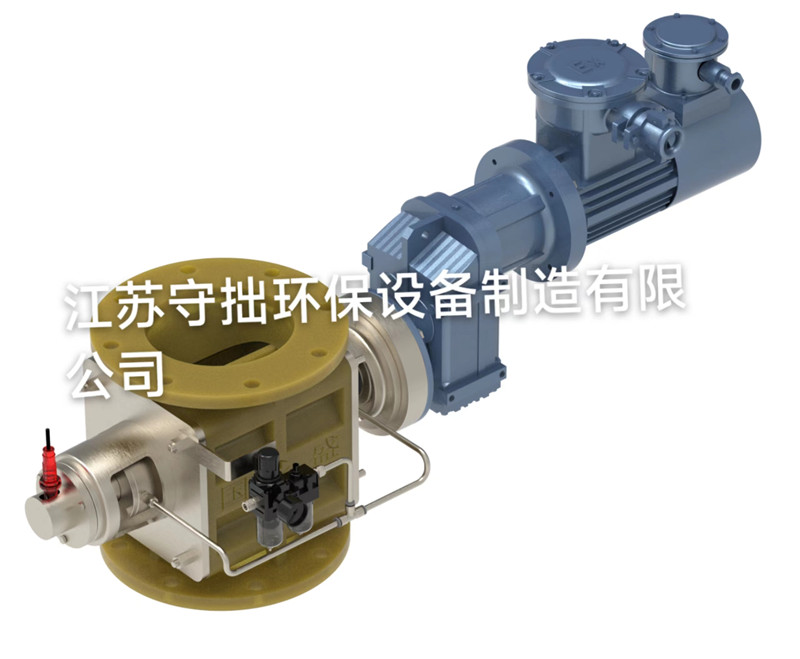

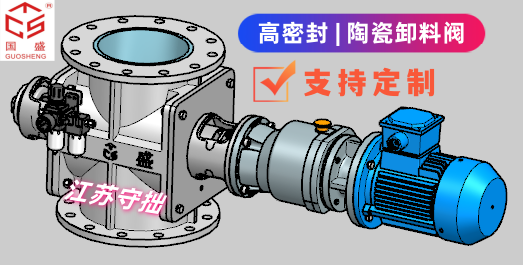

| 品名 | 鋰電旋轉閥,鋰電關風機,鋰電卸料閥,全陶瓷旋轉閥,內襯陶瓷旋轉閥,陶瓷旋轉卸料閥,陶瓷星型卸料器,襯陶瓷旋轉下料閥,陶瓷旋轉供料器,密封陶瓷旋轉閥,鎖氣陶瓷旋轉閥 |

| 介質 | 鋰電正負極材料,磷酸鐵鋰,三元材料,硅料,石墨,化工固體原料,硫酸鋁粉末,石油化工粒渣粉末,氫氧化鋁粉末 |

| 應用行業 | 鋰電,化工,食品,制藥,塑膠,鋼廠,電廠,礦山,環保 |

| 型號 | DN50~DN500,或方口,或非標定制 |

| 特點 | 防金屬接觸,耐高溫,耐腐蝕,耐磨,高精度密封鎖氣 |

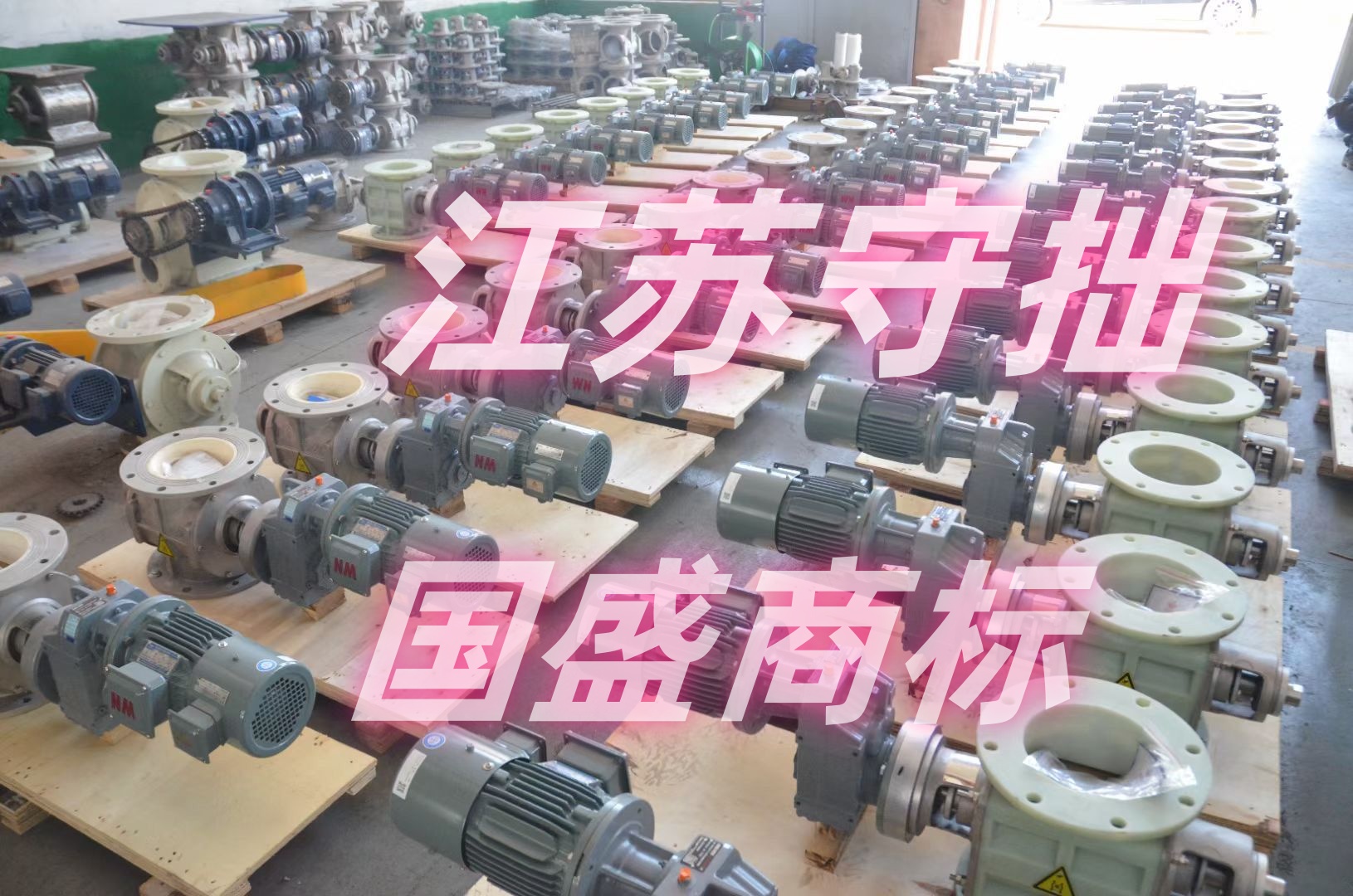

| 品牌 | 江蘇守拙,國盛,高端品牌 |

| 聯系電話(陳經理) | 18068546632 |

Lithium iron phosphate Phase II, auxiliary material feeding rotary valve: Auxiliary material density: 0.6g/cm3. 1. Material: Valve body 304. inner surface sprayed with ceramic, valve core entirely made of polyoxymethylene (POM) material, equipped with air seal; 2. Motor: Variable frequency regulation; 3. Supporting air source solenoid valve, air source hose. Feeding rate: 2t/h. Carbon source 1: 0.8g/cm3, Carbon source 2: 0.45g/cm3, Carbon source 3: 0.5g/cm3, material valve body 304. inner surface sprayed with ceramic, valve core entirely made of polyoxymethylene (POM) material, equipped with air seal; Motor: Variable frequency regulation; supporting air source solenoid valve, air source hose. Feeding rate: 4t/h.

陶瓷星型旋轉閥:

主要結構:外殼金屬;物料接觸部分:內襯陶瓷(也可全陶瓷、尼龍、四氟、特氟龍等)。

主要用于輸送鋰電池正極材料、磷酸鐵鋰、三元材料、化工、制藥等。

特點:耐高溫、耐磨、使用壽命長。

技術研發于2015年,批量生產于2017年,2020年更新第3代陶瓷星型旋轉閥,目前有陶瓷星型旋轉閥專利。

江蘇守拙主要定制高端旋轉閥:超級工程/重大項目/科研項目定制旋轉閥。【電話/微信咨詢:陳經理18068546632】

部分選用陶瓷旋轉閥案例:

磷酸鐵鋰二期,輔料投料旋轉閥:輔料密度:0.6g/cm3,1.材質:閥體304.內表面噴涂陶瓷、閥芯整體使用聚甲醛POM材質,配有氣密封;2.電機:變頻調節;3.配套氣源電磁閥、氣源軟管。下料速度:2t/h。碳源1:0.8g/cm3,碳源2:0.45g/cm3,碳源3:0.5g/cm3,材質閥體304.內表面噴涂陶瓷、閥芯整體使用聚甲醛POM材質,配有氣密封;電機:變頻調節;配套氣源電磁閥、氣源軟管。下料速度:4t/h。

輸送物料鋰電磷酸鐵鋰,溫度130℃左右;輸送量 19.2m3/h,電機功率:1.5Kw,旋轉閥尺寸:DN300.H400mm,16L/轉,40轉/分鐘,材質304不銹鋼,8葉片轉子、內腔陶瓷閥芯,M12*8法蘭孔連接,配備變頻電機。

出口用,輸送物料三元正極,要求旋轉閥支持快拆清理,全面禁銅鋅,物料接觸陶瓷材質。閥門對密封性要求極高,粉塵泄漏量不大于0.01mg/m3,產能2~3t/h。

DN200陶瓷星型旋轉閥,主體材質為SUS304.閥體及葉片表面冷噴涂陶瓷0.3m;兩邊端蓋板表面冷噴涂陶瓷0.3mm;進出口為HG/T20592 PN10標準DN200平面法蘭;配變頻減速電機,功率約0.75kw,能效等級IE4.防護等級IP55.絕緣等級F,脂潤滑:軸封方式為盤根+氣密封,軸承材質為SUS304;物料接觸及裸露部分禁銅鐵鋅。

物料:磷酸鐵鋰/石墨類,物料堆積比重0.3~1.2g/㎝3,法蘭連接DN200.流量要求:≥3t/h,材質SUS304內襯陶瓷,設備要求禁銅禁鋅,卸料閥(關風器)高度≤300mm,工況:上端常壓,下端負壓,防爆ExdllBT4.

物料:多晶硅粉,粉體,帶細小顆粒,DN100.容積0.6L/轉,工作溫度60-100℃,物料粒度:20-300μm,物料處理量400-500Kg,輸送壓力≥0.5Mpa,回轉閥填充系數0.6-0.7.回轉閥轉速29R/min,端蓋材質304.轉子材質304.外殼材質304(內襯陶瓷),端蓋形式:外置軸承式端蓋氣密封,主軸密閉做成硬密封,電機功率1.5kw-380-50hz,齒輪減速機國茂GKAF-59-48.89.

稀土精深加工粉末:陶瓷星型卸料閥,卸料介質:粉末;尺寸DN150.電機功率0.75kw,轉速33 r/min,閥座/閥瓣材質:陶瓷,輸送量>30L/h。密封:具備良好的軸密封,不允許粉塵進入軸承,造成損壞,也污染物料。驅動方式:馬達直連驅動,兩端面法蘭距離:<310mm。

物料:氧化鋁粉,氣力輸送系統配套不銹鋼旋轉閥內襯陶瓷,要求耐磨密封鎖氣,DN300.一小時卸料量不小于8噸,密度1.2~1.3.

物料:鋰電粉料,陶瓷星型給料閥,微正壓狀態使用,口徑DN300.葉輪與內壁單邊間隙30絲,葉輪和內壁是陶瓷。

鋰鹽生產線,規格:600*600; 能力:130m3/h(變頻)物料溫度:≤100 ℃,閥體耐熱,閥體材料:不銹鋼+內襯陶瓷,介質:細焙料(Li2O、Al2O3、SiO2),電機品牌:皖南電機、臥龍電氣電機。

化工廠用,物料類似食鹽結晶顆粒,DN200出料口,防爆電機,YBFBx5(Ex db ⅢC T5 Gb)防爆等級,外304不銹鋼,與物料接觸內襯陶瓷。

《掃二維碼-添加 陳經理 微信-咨詢陶瓷旋轉閥》

Rare earth deep-processing powder: ceramic star-shaped discharge valve, discharge medium: powder; size DN150. motor power 0.75kw, speed 33 r/min, valve seat/disc material: ceramic, conveying capacity >30L/h. Sealing: good shaft sealing, no dust allowed to enter the bearing, causing damage and contaminating the material. Drive mode: direct motor drive, distance between the two end flanges: <310mm.

Materials: Alumina powder, stainless steel rotary valve with ceramic lining for pneumatic conveying system, requiring wear-resistant sealing and air locking, DN300. with an unloading capacity of not less than 8 tons per hour, and a density of 1.2~1.3.

Materials: lithium battery powder, ceramic star-shaped feeding valve, used under micro-positive pressure, with a diameter of DN300. a single-sided clearance of 30 threads between the impeller and the inner wall, and both the impeller and the inner wall are made of ceramic.

Lithium salt production line, specifications: 600*600; capacity: 130m3/h (variable frequency); material temperature: ≤100 ℃, valve body heat-resistant; valve body material: stainless steel + ceramic lining; medium: fine calcine (Li2O, Al2O3. SiO2); motor brands: Wannan Electric Motor, Wolong Electric Motor.

For use in chemical plants, the material resembles salt crystal particles. It features a DN200 discharge outlet, an explosion-proof motor, and an explosion-proof rating of YBFBx5 (Ex db ⅢC T5 Gb). The exterior is made of 304 stainless steel, while the interior lining that comes into contact with the material is made of ceramic.

-

—— 售后服務

我們將繼續利用技術產品優勢,不斷地改善設備工藝,加強質量管理,完善售前、售后服務,為顧客提供高質量的產品和服務,衷心與您攜手前進、誠信合作、共創美好未來!

-

—— 高質量產品服務

專業定制高端旋轉閥,科研項目定制旋轉閥,重大項目級定制旋轉閥,替代國外進口品牌旋轉閥。建立了有效的質量管理體系和的售后服務體系,為顧客提供高質量的產品和服務。

-

—— 誠信經營

我們本著誠信經營的原則,以技術、服務做為企業的核心競爭力,積極進取,勇于開拓,經過多年的努力拼搏,已成為行業中的佼佼者。